This time, we traveled to Emei Township, located in the southern part of Hsinchu County. We had only been here once before to visit Nature Loving Wonderland, a Maitreya Buddha Temple. Anyway, before moving to Tainan, I wanted to visit some historical places in Hsinchu and found an old tea factory in Fuxing, Emei.

When we arrived there, we found an old man in the factory, but he didn't introduce anything. He was just sitting there, looking unhappy and drinking tea. There was a room where a video should have been played, but it was turned off. The building wasn't well-maintained. Part of the roof was leaking, and the water had damaged a few machines. Additionally, the upper floor was blocked off and inaccessible.

Tseng Family History

The Tseng Family's ancestors came from China and settled down as farmers in Miaoli. In 1853, they moved to Fuxing, bringing uncultivated land under cultivation and acquiring more lands. They became the most prestigious family in Fuxing and also played a leading role in local affairs. They initiated the construction of Longsheng Temple in 1890, which became the center of belief in Fuxing. They provided funds and efforts for the subsequent repairs and reconstructions of the temple.

Mr. Tseng Sin-gu is the founder of the Fuxing Tea Factory. He devoted himself to local public affairs. As part of the Emei Township Farmers Association in 1951, he requested a large number of subsidies for warehouses, offices, rice mills, and a duty room. He also funded the construction of a waterworks system and supported engineering projects in Fuxing. As a result, in the 1950s and 1960s, the people in Fuxing had access to clean tap water and stable power supply.

See also: Guanxi Tea Factory

The production of tea in the Fuxing Tea Factory (富興茶葉文化館(老茶廠)) is closely related to the tea industry in Taiwan. Taiwan Black Tea began to gain prominence in 1928 and reached its peak in 1937. Initially, black tea, green tea, and oolong tea were produced here and exported to Europe and North Africa. During that time, Hsinchu was the largest production area for black tea. The Fuxing Tea Factory was founded in 1944 and started its tea production business by producing crude black tea. Before the construction of its new factory, the major place for producing crude tea was the "Chaliao" (tea dorm).

At that time, there were only three tea factories in Emei Township. According to the data from 1951, the Fuxing Tea Factory was roughly 430 square meters in size, with 3 employees, 11 workers, and the largest amount of tea produced reaching 133,800 kilograms. The Fuxing Tea Factory was the number one tea factory among the large tea manufacturers in Hsinchu County.

The development of the tea industry shifted from the production of black tea to the exportation of roasted green and steamed tea. In the 1980s, a large number of workers migrated outside the area, and workers' wages increased, causing the production costs to rise. Meanwhile, the tea industry in central and southern Taiwan flourished. All these factors had an impact on the Fuxing Tea Factory. Tea production decreased and eventually ceased in 1991. However, the tea-making equipment was preserved and carefully cleaned. In 1995, the Cultural Bureau registered this factory as a historical building. Inside, you can find a tea museum where you can learn about the tea-making process.

Inside the Fuxing Tea Factory

The withering room on the second floor of the factory was an important space. In the production of black tea, the leaves must be rolled immediately after withering. For the convenience of moving withered tea leaves to the first floor, there were holes on the floor with rolling machines located below. The tea was sent into the machines through pipes.

Humidity in the air plays a significant role in the production process, especially during withering and fermentation. To fully adjust the temperature and humidity, the tea factory had many windows. The factory had undergone several reconstructions in different periods.

During the earthquake in 1935, the factory was destroyed. The walls in the front section still remain as they were built 100 years ago, although other departments were reconstructed. The building materials are mainly eucalyptus, which is durable and resistant to insects, allowing it to maintain its original appearance.

When the new factory was under construction in 1935, the entire structure was made of brick, with only the upper edges and eaves of the doors and windows built with reinforced concrete. The tea factory was also expanded and transformed several times. In 1950, additional space was added to meet the growing demand for black tea. The roof was used for withering under sunlight, while the indoor area was used for producing crude black tea. From 1951 to 1961, the production of tea shifted to green tea. The right space of the factory was expanded to accommodate blanching machines and the family's main entrance.

The Tea Factory consisted of both production and living spaces. It was the only two-story building in Fuxing. The second floor contained the withering space with its equipment, while the main production space equipped with a variety of machines was located on the first floor. The floor and roof trusses on the second floor were made of wood and covered with traditional red flat tiles. The office and living spaces surrounded the factory.

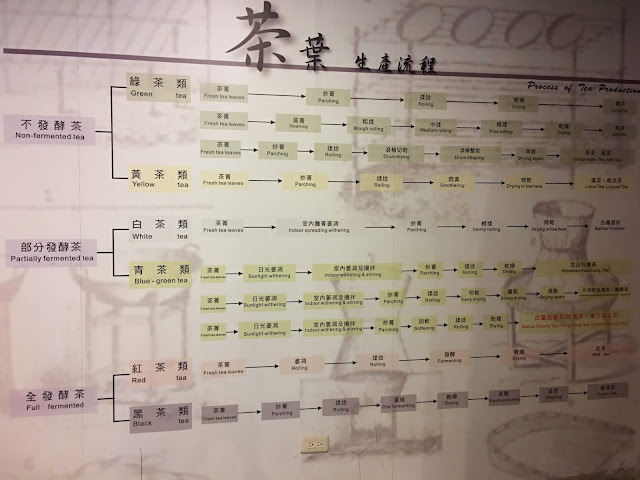

Tea Production process

Fresh tea leaves:

Tea leaves are picked from tea trees. Usually, the young stems of tea leaves are carefully pinched using the thumb and forefinger. Different parts of tea leaves are picked according to different varieties of tea. For example, some pick the terminal bud and the first leaf next to it (one-bud-one-leaf), some pick two leaves (one-bud-two-leaves), and some pick one bud and three leaves.

Withering:

Withering can be done through "sunlight/hot air withering" or "indoor withering".

In the first process, sunlight or hot air is used to evaporate the water from fresh tea leaves and lower the cell activity. This allows the chemical components, especially catechin, to undergo fermentation. After this process, the tea leaves must be stirred and placed indoors for further withering.

Workers use both hands to stir the fresh tea leaves, causing them to rub against each other. When the leaf margin is damaged and exposed to the air, it facilitates fermentation and evaporation of water content. Later, the tea leaves must be spread out separately for a while before being gathered.

Blanching:

This process can be divided into two types: "parching" and "steaming". In Taiwan, the process of parching is mostly used.

In parching, high temperatures are used to destroy the enzyme activity and prevent continuous fermentation of tea leaves. This helps maintain the special fragrance and soft texture of the tea leaves, making them easier to roll into a bar shape and then dry.

Rolling:

There are two methods of rolling. The first method involves putting tea leaves into a rolling machine for pressing and rolling. The other method involves wrapping tea leaves in cloth and manually pressing and rolling them into a ball shape. Under pressure, the tea leaves take on roll, spherical, and hemispherical shapes. During this process, parts of the tea leaf tissues are destroyed, making them easier to brew.

Separation:

After rolling, tea leaves become twisted together due to the tea juice, making them difficult to dry. Before the drying process, the tea leaves need to be separated.

Drying:

Tea leaves are dried in a dryer machine. High temperatures are used to suppress the remaining enzyme activity in the tea leaves. Once dried, the tea is called "crude tea" or "raw tea." It requires further refinement to become a high-quality tea product.

0 komentarze:

Post a Comment